Belaboring the point: Cultivating talent starts at the top

Cultivating talent starts at the top

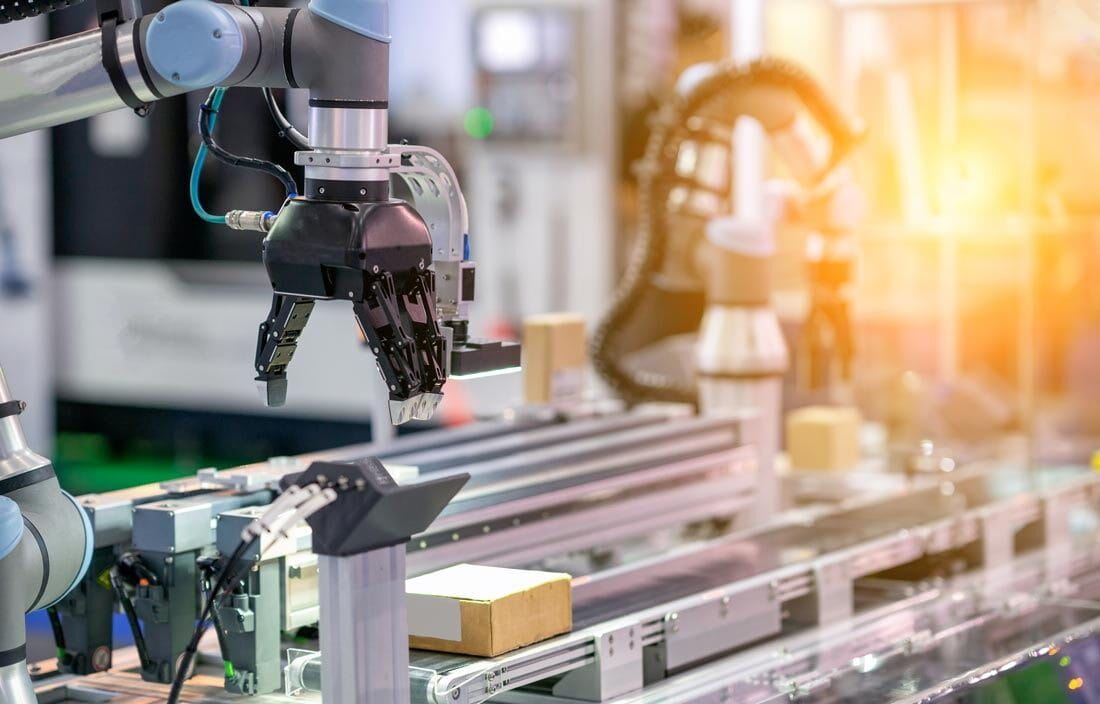

The outlook for manufacturing is improving but finding skilled labor remains a major concern for manufacturers, particularly in the middle market. Companies’ underinvestment during the downturn in their skilled manufacturing workforce and, as a result, in the potential for innovation that workforce brings, now threaten to impede growth during the recovery and beyond.

At the same time, while unemployment within the sector is dropping, we haven’t seen the degree of upward pressure on wages we would expect in a true shortage. Several experts have suggested the gap in manufacturing talent may be less skills-based than wage- and perception-based. The public’s image of manufacturing — physically demanding, dirty, repetitive, male-dominated, low-paying — may not yet have caught up to the increasingly high-tech manufacturing environments of today.

Among Gen Y-ers, aka Millennials, many of whom live much of their personal and professional lives online, a career in manufacturing may seem less appealing than one in digital media, finance, or IT. This generation has had far fewer opportunities to take shop and other vocational or occupational classes in high school. According to the National Center for Education Statistics, high school grads earning career and technical education credit in manufacturing dropped by almost 10 percent from 1990 to 2009. But the sector needs Millennials since about one-third of the industry’s current workforce is between 55 and 64 years old.

Taking the training reins

Historically, manufacturers played a much greater role in developing talent than they do today. Think Henry Ford Trade School and General Motors Institute, for instance. More recent examples include Merrill Fabricators’ Merrill Institute and Automatic Feed Company, which created a novel collaborative program, the Northwest Ohio Learning Center for Manufacturing Sciences, with area community colleges and high schools.

In Grand Rapids, Mich., Pridgeon & Clay, which provides metal-stamped and fine-blank components for the auto industry, teamed up with other area manufacturing firms and the PrecisionMetalforming Association to host facility tours for high school students. The company, with over 1,000 employees, also created a Career Paths program for skilled trades that includes paid positions in conjunction with flexible hours and education reimbursement toward an associate’s degree.

Pridgeon & Clay also offers a 12- to 18-month press operator apprenticeship program. Over 20 classes have been developed and are taught on-site, and the program has been recognized with the Precision Metalforming Association’s A.R. Hedberg Award.

Granted, such programs can be expensive, and of course there’s no one perfect, or quick, solution or model. Yet not taking charge also carries costs. Companies must think creatively about how to cultivate the talent they need, now and into the future. In short, manufacturers need to develop the people they want to recruit.

Culture: The recruiter's and innovator's, best friend

As manufacturers consider strategies and tactics to attract talent, they shouldn’t lose sight of one factor that is well within their control: culture.

“Culture creates an environment that ‘A’ players want to be part of,” says Ed Holland, CEO of M. Holland, a distributor of plastics resins. “It plays a huge role in recruitment and retention. It’s one of our differentiators.” Holland says the company’s core values, generous benefits, and innovative environment all keep current employees excited and attract new top talent.

Your culture doesn’t only draw talent to your door, it helps keep that talent a productive, motivated source of innovation. Plante Moran’s 2014 Innovation Study: Is Your Corporate Culture a Catalyst for Innovation? explores how elite organizations use culture to engage employees and spur innovation. As one survey participant commented, “They [employees] drive the innovation, and the rest of the organization follows.”

Among elite organizations, defined as organizations that saw a 30 percent or more increase in revenue over the past one to three years, four categories of cultural and workplace practices emerged from the survey results:

- A collaborative work environment

- Programs and tools to support innovation

- Work-life balance programs

- Perks and benefits

A culture that fosters open communication and rewards creative thinking is key to motivating employees to take the kinds of risks that innovation demands. Elite organizations found that collaborative workspaces and team- and trust-building programs help create a positive environment. These companies recognize employee contributions through awards ceremonies and incentives. Interestingly, successful firms found nonmonetary recognition more effective than monetary incentives, suggesting that such programs don’t have to cost a lot.

The most innovative organizations also believe that the right training is crucial to helping employees generate innovative ideas. These companies reported offering both formal and informal training programs, access to continuing education, and tuition reimbursement.

Investing in talent in not optional

While the benefits of talent development programs are clear, many companies are hesitant to invest in current and prospective employees only to have them leave for a job with a competitor. Of course that’s a possibility, but investing in your workforce is necessary, not a luxury, and you may have more control over the return on that investment than you think.

“You have to protect your ‘A’ players,” said Holland. “That ties back to culture, making people feel they belong and giving them opportunities to grow with the organization. One of the things we’re told we’re good at is allowing people to rise to where their talents take them.”

The company has undertaken a number of recent talent-related initiatives, including creating M. Holland University, establishing a scholarship with the Plastics Pioneers Association, investing in a collaborative electronic performance management system, and developing an extensive onboarding and orientation process for new employees. “Motivated individuals love this environment,” Holland said, “because they can feel valuable.”

Companies that can offer employees challenging but rewarding growth experiences indeed have an edge, according to Scott Becker, CEO of Chromaflo, which makes pigment dispersions for thermoset plastics and the Coatings industries. The company is based in Ashtabula, Ohio, with plants and technical labs on six continents.

“That was one of the benefits to us of expanding internationally,” Becker says. “It’s created a good growth opportunity for everybody who works for us and also created career opportunities that would not have been available had we stayed just a North American company. Many of the people who work for us travel internationally now, and they manage people internationally. It’s given them exposure to other customers and cultures and processes that they just would not have experienced otherwise. Those kind of opportunities keep people with us.”

Short-term, high-impact

Cultivating talent, both outside and inside your organization, takes time. Outreach and STEM initiatives targeting students take time. Yet, as you likely know all too well, the talent issue looms today. In the short term, companies should consider easy-to-implement programs that can have an impact in the near-term. Consider instituting tuition reimbursement for relevant college courses and continuing education and/or partnering with local community colleges to co-develop courses that teach the skills your firm, and perhaps other local firms, need.

Also take a hard look at your onboarding and performance appraisal processes. Are you bringing employees into the fold from the get-go, so they feel a sense of belonging, understand their role with respect to company goals, and see growth opportunities? Are you identifying promising talent early in order to provide mentorship and training to address gaps in skillsets, be they technical or “soft”?

While it’s easy for near-term needs to eclipse long-term planning, consider your talent needs three, five, 10 years from now, especially in light of current and anticipated market trends. Talent recruitment and development strategies need to be part of your overall business strategy, not only to keep operations humming today but to grow, innovate, and thrive over time.