Over the past several years, healthcare supply chains have been challenged by insufficient essential supplies, excess unnecessary supply, and price gauging. In addition, unpredictable and significantly decreased patient volumes, coupled with rising inflation, have further stressed nonoptimized supply chains. To better position themselves for market and economic challenges, hospitals and health systems with high-performing supply chains have increased their visibility across the network and prioritized internal process improvement, efficiency enhancement, and margin improvement. How is your hospital or health system addressing its inventory risks and adapting to the need for a resilient supply chain? One key step is optimizing your inventory management program.

Considerations for evaluating hospital inventory management

Optimizing how your healthcare organization manages inventory requires looking at your hospital’s inventory management processes and systems. This includes reviewing supply-related spend, KPI tracking, and leveraging electronic tools. Begin by asking the following three questions:

1. What percentage of your organization’s overall spend is supply-related? Do you know what it should be?

Understanding how much of your total hospital spend is inventory-related and how that may have increased or changed over the last few years is crucial to identifying areas for improvement and opportunities for growth.

If you have access to benchmarking tools, compare your overall supply spend to peer organizations. This provides the opportunity to review inventory management practices, align with industry standards, and potentially reduce supply spend through cost containment measures.

2. Are you tracking KPIs related to inventory management?

A few of the metrics your organization should be tracking include:

- Inventory turns

- Percentage of items expired

- Vendor on-time deliveries

These are critical to understanding individual departments’ inventory needs and usage trends. Tracking these KPIs also supports your team’s ability to effectively manage inventory and drive bottom-line savings.

3. Is your healthcare organization leveraging electronic supply chain management tools?

Having all items and item locations recorded in an electronic inventory system is the first step toward leveraging data to optimize inventory management. Many of these tools offer KPI reporting, real-time tracking of PAR (periodic automatic replenishment) levels, and forecasting that allow your materials management teams to better predict supply needs, minimize waste, and leverage volume pricing to reduce costs.

Ensuring standardization in inventory management

Successful inventory management and optimization in your hospital or health system depends upon standardization. This includes both standard inventory management processes and standardized supply vendors.

A lack of standardization leads to waste and missing inventory, while standardizing processes enables efficient movement and use of inventory. Standardization also includes defining roles. Identifying who’s responsible for each process or step of the process helps avoid redundant work effort, increases staff productivity, and drives accountability among functions.

Standardization should also apply to physician- and specialty-specific inventory. Often, when hospitals order supplies for specific specialties or providers, they see increased rates of waste, higher costs, and expired products on the shelves, which can increase patient safety risks. Standardizing physician- and specialty-specific supplies as much as possible and reducing the overall number of vendors and suppliers at your organization can help alleviate this.

Leverage a 6S lean initiative to optimize hospital inventory management

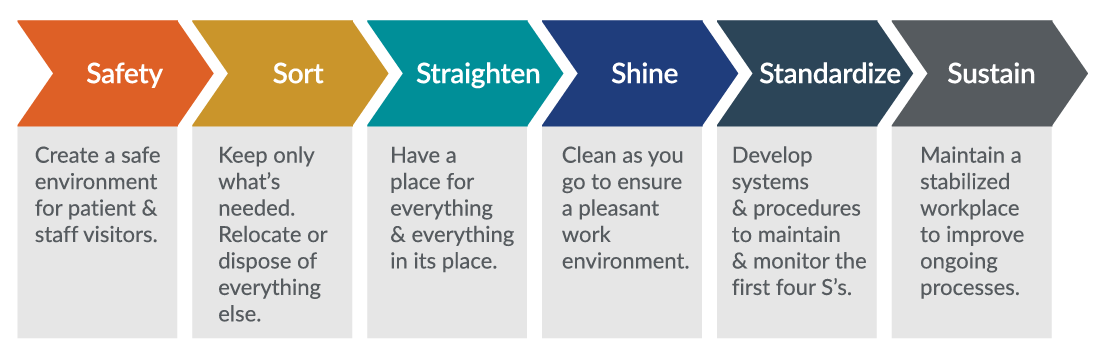

Consider a 6S event to organize supplies and optimize inventory management systems. What is a 6S? The acronym “6S” stands for safety, sort, straighten, shine, standardize, and sustain, and a 6S initiative provides a starting point for continuous improvement and sustainable performance excellence.

A 6S project can be launched to:

- Increase organization.

- Improve the quality of work.

- Reduce costs.

- Create a safer work environment.

- Improve workforce morale, ease of job tasks, and staff satisfaction.

For hospital inventory management, a 6S is a systematic way of creating a safe, efficient, and highly visible workspace for hospital staff members. Let’s break 6S down:

- Safety: Identify hazards and establish preventive controls to keep staff safe. This also helps ensure compliance with necessary safety protocols.

- Sort: Reduce clutter and ensure staff can locate items easily. Staff should start with clearing and classifying items and removing everything that’s not useful.

- Straighten: This process includes organizing all remaining items. In healthcare spaces, it’s best practice to use ergonomic principles to locate items to minimize movement and reaching. The objective is to identify items and ensure they have a “home.” Creating visual cues and identifying the amount of inventory needed for each item can also be helpful.

- Shine: Once the unnecessary items are discarded and required items are stored and organized, the workplace needs to be cleaned. Staff should ensure the area remains neat and tidy; this includes cleaning and inspecting the overall space, sweeping floors, wiping down shelves and containers, etc.

- Standardize: Standard work ensures staff adopt new workplace norms by following best practices and creating routine procedures. This supports staff by simplifying work routines and developing more efficient processes. It’s best practice to establish visual cues, set employee expectations, and conduct regular inspections or audits to support sustained standardization.

- Sustain: This includes ensuring that the processes put in place are followed and applied consistently over time. This is one of the most challenging steps of the 6S method. Successful organizations have regular reviews and internal audits and standard practices in place that allow them to more easily sustain their 6S efforts.

Supply chain resilience is an organizationwide benefit

A more resilient supply chain helps your healthcare organization ensure you have the right inventory on hand to deliver care and help keep patients safe. Consider taking steps to assess and optimize your hospital inventory management program. Supply chain risks won’t go away. Is your hospital or health system prepared to face the next disruption?